which of course may just reflect the limitation of my needs! but I can't think of a situation in which that would be worthwhile for my needs. Put -.01mm into the tolerance parameter, regenerate the model again, and now you will see what it will look like if every single part is at the minimum possible tolerance.

01mm into the tolerance parameter, regenerate the model, and voila - now you see what the whole thing will look like if every single part is at the maximum possible tolerance. Let's say the tolerance for the parts is +/-.01mm. But when this goes down on paper, the part is drawn just to one size, and the tolerances are added as text to that drawing - at least, as far as I have ever seen.Īctually, it would be possible in FreeCAD to build the model up using parameters (which I routinely do), including a tolerance parameter (which I have never done, but certainly possible to do). Of course, the designer must to take into account the potential effect of stacking of tolerances, and design and determine tolerances accordingly. And again I stress, I'm talking about the modeling (or in this case, the actual drawing) of the part. I would have thought this would be similar to the "old fashioned" approach using paper and ink - surely one of the master draftsmen of the past did not try to draw in the different possible locations of the edge of the part to allow for a +/- tolerance? Again, please forgive my ignorance - maybe this is exactly what they did, and I just haven't ever seen an example of it. (In the drawing that is made from the model, yes, but not in the modelling itself.)įWIW, in my use of FreeCAD to date, I model things to "exact" dimensions, and then put in the tolerances when I produce the drawings.

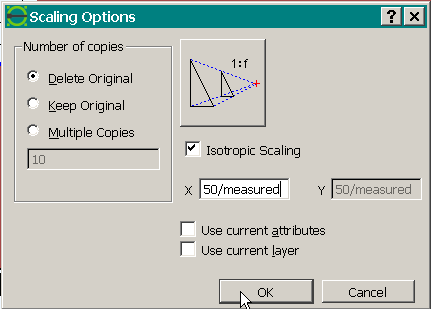

I have seen only bits and pieces of how other programs work (e.g., in the course of YouTube videos where someone demonstrates how Fusion 360 was used to draw up a part or a whole project), but never in any of those bits and pieces have I seen anyone ever enter a tolerance into the modelling. I do fully understand the issue of tolerances! What I don't understand or have any experience with is how other programs might build the tolerances into the modelling process. Short answer: No, it doesn't really help, but that is probably my limited experience / understanding. The range of pipe schedules is missing more than one or two items never mind their sizes - there are other such issues.) (Also FreeCAD devs mostly seem to have worked with a tiny bit of what is available out in the real world - see anything that includes pipe in their software. Tolerance direction - most often tolerance are + and - a certain amount - if a interconnected group of parts are all produced to the high side - or conversely to the low side - well there are now fit issues. (Tolerance stacking occurs when a number of parts are connected - if every part is at the high end of the tolerances you will get quite a different assembly than if all the parts are at the low end of the tolerances (gets very important when you're playing with precision stuff - most commonly found in having bearing pockets and also machined shafting). There are lots of problems that are created when tolerances are not included - some of which are tolerance stacking, and tolerance direction for just two. So when I cannot include any tolerancing the dimensions become almost worthless. Including ALL the important information in any kind of drawing is crucial imo. Bearing information will give you the needed housing size, with those tolerances, and the shaft size, and its tolerances. I was working on a fairly high speed mechanism (looking for up to 10 500 rpm as a design max - limited by bearing capabilities in fact). In FreeCAD you are asked for a numeric value for the dimension - you cannot - at least I've never found a way to use it when modelling - you just cannot input something like 62.000 +0.000/-0.005 mm say for a bearing housing.

(Grab a piece of pipe and chuck it up - run an indicator on it for one example.) As a machinist - it became very clear that NOTHING is exact.

0 kommentar(er)

0 kommentar(er)